Starship Compendium

This article will be regularly updated based on the latest information (list of recent changes can be found at the end of the article). You can easily access the article from the main menu in the “Compendiums” section.

Super Heavy Starship (SHS) is a proposed super heavy-lift launch system designed by SpaceX for missions to Mars, the Moon and many other applications. It could become the largest rocket in history and is expected to eventually replace all current SpaceX spacecraft. Thanks to complete reusability and capability to refuel in orbit, SHS could provide low-cost transportation of cargo and people to virtually anywhere in the Solar System. On top of that, this new rocket can theoretically be used as an extremely fast transport system between any two points on Earth. In this article, you will find all the important and most up-to-date information about Super Heavy Starship, which is being built right now.

Note: To prevent confusion, I’m calling the entire stack “Super Heavy Starship” to differentiate it from “Starship”, which I’m using only for the upper stage/spaceship portion of the vehicle.

Last Update: July 1, 2020

(changelog)

Skip to section:

- Project History

- Super Heavy Starship System

- Stainless Steel vs. Carbon Composites

- Thermal Protection System

- Raptor Engine

- Super Heavy (First Stage)

- Starship (Second Stage)

- Launch and Landing

- SHS Production

- Starhopper Test Vehicle

- Starship Prototypes

- Launch Pads

- SHS Applications

- Financing the Development of SHS

- Project dearMoon (Lunar Flyby)

- Moon Missions

- Mars Missions

- Relevant Links and Videos

Project History

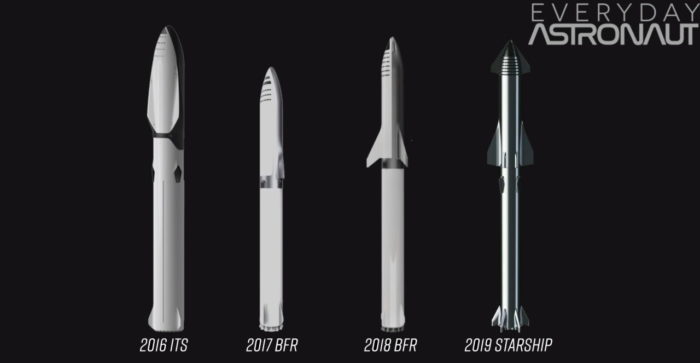

Super Heavy Starship is the latest iteration of the Big Falcon Rocket (BFR), formerly known as Mars Colonial Transporter, which was first publicly presented in 2016 under the name Interplanetary Transport System (ITS). At that time, the rocket had a diameter of 12 meters and a height of 122 meters. A year later, however, SpaceX CEO Elon Musk introduced a revised version that had a 9-meter diameter and a height of 106 meters. Musk called it BFR, which until then was only the internal designation of the project. In addition, this scaled-down BFR was newly equipped with a small delta wing for better maneuverability in different environments, as the ship is designed to be operated not only on Earth and Mars, but also on the Moon or basically anywhere in the Solar System. Then, in 2018, the BFR underwent additional changes, the most significant of which was the addition of several aerodynamic surfaces to help stabilize the ship when passing through atmospheres of Earth and Mars.

The hull and tanks were originally made of carbon composites, and over the years, SpaceX produced several rocket parts using this material. In 2016, the company showed a giant oxygen tank for the 12-meter-diameter ITS rocket. However, in February 2017, the tank was destroyed during testing (intentionally, according to Elon Musk). Subsequently, a smaller BFR variant was introduced, and during 2018, production of a 9-meter tank began.

But at the end of 2018, Elon Musk announced that Falcon 9 and Falcon Heavy would not receive any more major upgrades and the company will instead focus on the development of Super Heavy Starship. At the same time, we learned that SHS would use stainless steel instead of carbon composites. When asked what was the main reason for such radical rocket design changes, Musk replied: “Time. Although it also turned out to be dramatically better.” The updated design was publicly presented in September 2019.

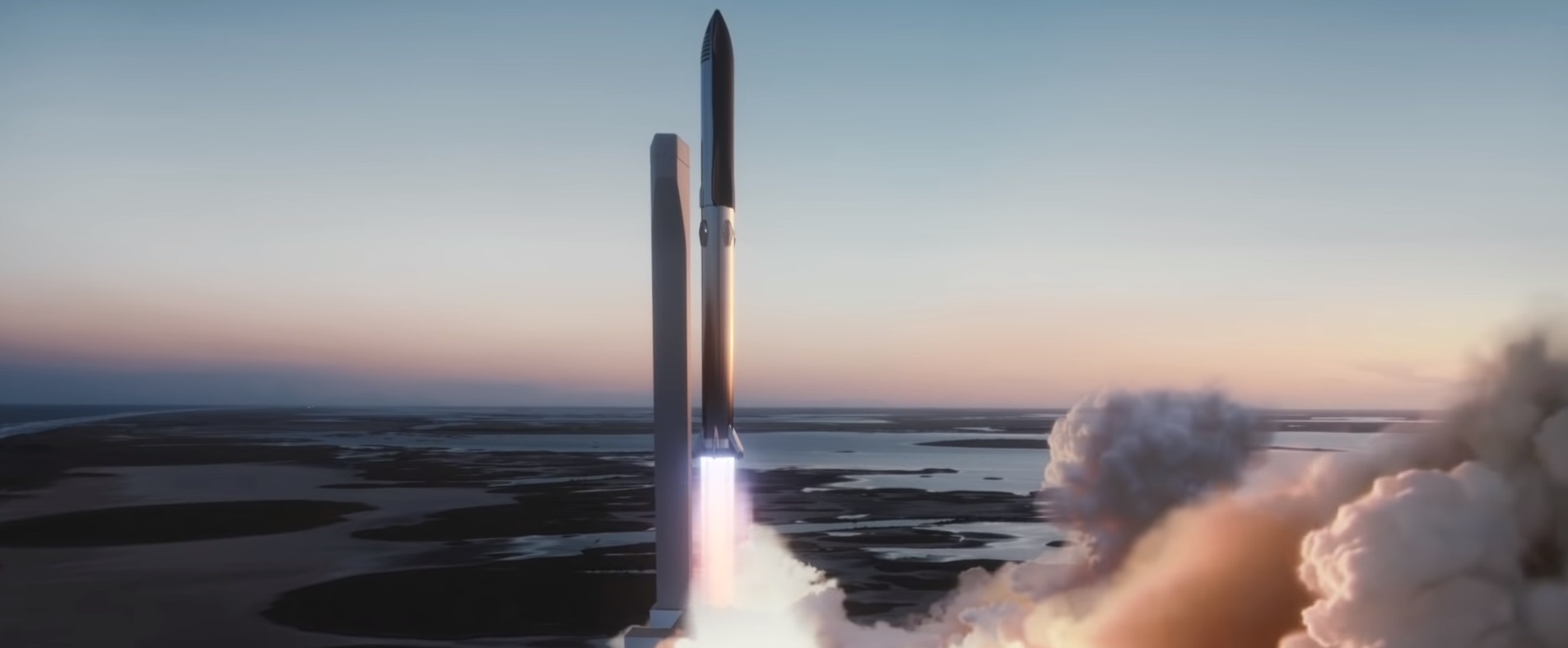

Super Heavy Starship System

The first stage of the rocket is called the Super Heavy and the second stage is called Starship. According to Elon Musk, it is also possible to use the term “Starship” for the entire stack. Both stages are 9 meters in diameter and together they measure 120 meters in height, making SHS the tallest rocket ever (Saturn V was 111 meters tall). According to Elon Musk, SHS would be able to deliver between 100 and 150 metric tons to low Earth orbit. In the case of launching to a standard geostationary transfer orbit with 27° inclination, the payload would drop to 21 tons (however, Musk estimated 30 to 40 metric tons in the past). All these values are for a “fully reusable config” and would actually be “about double in fully expendable config, which is hopefully never”, according to Musk.

SHS will have the highest payload capacity of all the rockets in history, yet due to its complete reusability, it will also be the cheapest rocket in terms of marginal cost. Price per launch is expected to be in single-digit millions of dollars. In contrast, Falcon 9 costs at least $50 million USD. Musk commented on the price: “This will sound implausible, but I think there’s a path to build Starship / Super Heavy for less than Falcon 9.” Musk also believes that Super Heavy Starship’s cost per kilogram of cargo to low Earth orbit will be at least 10 times lower than Falcon 9.

After launching, Starship can either put cargo into orbit and then land back on Earth, or it can wait on orbit for other ships to fill it up with fuel and oxygen, and then head for the Moon or Mars with full tanks. Refueling takes place by connecting two ships in low Earth orbit together at the aft end and then accelerating slightly with RCS to move the liquids in the desired direction. Fully refuelled Starship with 100 tons of cargo, placed in a highly elliptical Earth orbit, would have about 6.9 km/s delta-v. That would allow it to go to the Moon, land and come back to Earth without refuelling. In the case of Mars, however, the ship would need to refuel with propellants produced directly on the Red Planet. Starship can then take off again and return to Earth with 20 to 50 tons of cargo.

Like the Falcon 9, Super Heavy Starship uses subcooled fuel, which allows the rocket to carry 10 to 12% more of it in the same volume. But unlike Falcon rockets which use kerosene, SHS will burn methane. SHS will contain 4,800 tons of propellants (78% oxygen & 22% methane).

RCS thrusters on both rocket stages were originally supposed to be quite powerful, use methane and, according to Musk, “will be closer in design to the Raptor main chamber than SuperDraco and will be pressure-fed to enable lowest possible impulse bit (no turbopump spin delay).” Eventually, however, the plans were simplified and Elon Musk announced that SHS would only be equipped with less powerful cold gas thrusters, simplifying things greatly. In the future, these would be replaced with the powerful methane thrusters because they’re useful during landing (also on the Moon).

In the case of Falcon rockets, tanks are pressurized with helium that is contained in pressure vessels located inside fuel and oxygen tanks. In contrast, the tanks in SHS would be pressurized autogenously using gaseous methane or oxygen routed from the engines, eliminating the need for a separate helium system. Musk said that this new tank pressurization method would be implemented in the first version of the SHS, however Starhopper still used helium as pressurant.

Stainless Steel vs. Carbon Composites

Regarding the transition from carbon composites to stainless steel, Elon Musk explained it in more detail to Popular Mechanics. SpaceX has chosen high quality 301 grade stainless steel, which should be an austenitic stainless steel with high chromium and nickel content. Elon Musk also said that some parts of the ship would use 304L steel which is stronger at cryogenic temperatures. This type of steel was tested for the first time in June 2020 using a test tank SN7. In late 2020, SpaceX wants to switch to a custom alloy 30X which “will be better“. Tesla Cybertruck is supposed to be made from the same alloy. Musk also mentioned 310S steel that would be used on those parts of the ship that would experience the highest temperatures on reentry. But it’s unclear if that’s still the plan.

The main advantages of the mentioned steel alloys are excellent properties at both low and high temperatures, they’re easily workable and have low cost (according to Musk, stainless steel is about 60 times cheaper than carbon composites). Starship will also need to be easy to repair on the Moon or Mars, and to work on steel, you only need a regular welding machine. Moreover, according to Musk, the transition to steel will counter-intuitively lead to an increase in the rocket’s payload capacity, not a reduction.

Old Atlas rockets also used steel tanks which had to be constantly pressurized with gas, or the whole thing crumpled. However, Starship is designed differently and does not collapse under its own weight.

Thermal Protection System

Thanks to steel’s higher melting point, the new metal SHS design will require “much less” thermal protection. That fact compensates for the higher weight of steel compared to carbon composites. This means that Starship’s leeward side does not need any heat shielding. On the windward side, Musk wanted to use the very first regenerative heat shield:

A double-walled stainless shell—like a stainless-steel sandwich. You just need, essentially, two layers that are joined with stringers. You flow either fuel or water in between the sandwich layer, and then you have micro-perforations on the outside—very tiny perforations—and you essentially bleed water, or you could bleed fuel, through the micro-perforations on the outside. You wouldn’t see them unless you got up close. But you use transpiration cooling to cool the windward side of the rocket.

In September 2019, Elon Musk explained that the transpiration cooling could have been developed but SpaceX instead decided to go with robust reusable tiles which end up being lighter overall.

When returning from a low orbit, about 20% of the ship’s surface would be exposed to a maximum temperature of about 1476 °C (1750 K), an additional 20% to 1326 °C (1600 K), and the rest of the surface would reach a maximum temperature below 1176 °C (1450 K), which the 310S steel could withstand without any additional cooling. As for the temperatures that the Super Heavy booster would be exposed to on reentry, Musk explained that the temperatures on the hottest parts of the rocket should not exceed 330 °C (600 K) and the temperatures around the engine section will not exceed 925 °C (1200 K). Steel can handle those temperatures with just passive radiative cooling.

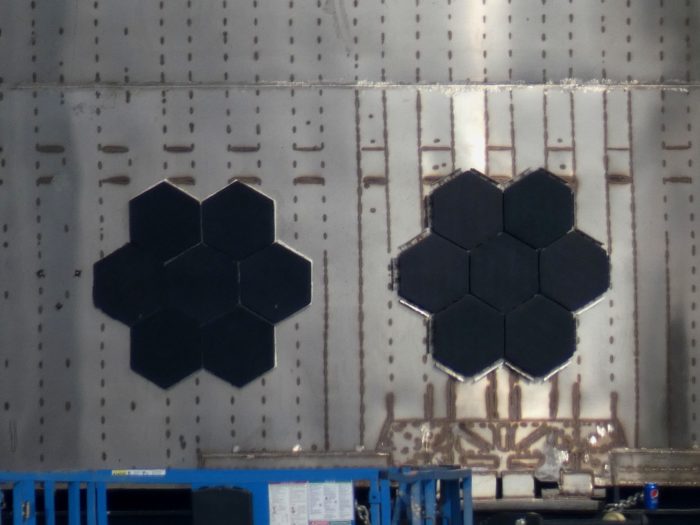

Testing metallic heat shield at 1100C (2000F) @SpaceX pic.twitter.com/frP5eZ5a0z

— Elon Musk (@elonmusk) January 25, 2019

Testing Starship heatshield hex tiles pic.twitter.com/PycE9VthxQ

— Elon Musk (@elonmusk) March 17, 2019

Later, Musk explained that most of the windward side will consist of hexagonal tiles. Their shape was chosen because that way there is “no straight path for hot gas to accelerate through the gaps.” During the CRS-18 mission in July 2019, SpaceX tested ceramic tiles meant for Starship’s heat shield. Elon Musk then offered more details about these tiles in response to a tweet saying that the highly reflective surface of Starship might not be desirable. Elon Musk responded with a series of tweets:

High reflectivity minimizes photonic heating, high emissivity minimizes particle heating. No need to radiate heat away if you aren’t hot in the first place. Also, as metal heats up to yellow/red/white, it stops being reflective.

Testing a possible Starship windward side ceramic tile. Maximizing emissivity is best for conductive/particle heating. Nice thing about steel is that tiles can be very thin, unlike carbon fiber or aluminum airframe.

Thin tiles on windward side of ship & nothing on leeward or anywhere on booster looks like lightest option.

However, Musk did not say what material the hexagonal tiles or the CRS-18 tiles were made of. Current heat shields on Dragon spacecraft use PICA-X but that’s an ablative material that isn’t desireable for the highly reusable Starship. It’s been speculated that the ceramic tiles could be made of TUFROC (Toughened Uni-piece Fibrous Reinforced Oxidation-Resistant Composite) because SpaceX and NASA have been collaborating on its development since June 2018.

This technology was originally developed at NASA Ames and was used successfully on the X-37B spacecraft. As reported by Parabolic Arc, TUFROC consists of a high temperature, impregnated carbonaceous cap mechanically attached to a lightweight fibrous silica-base material. The key innovations enable the integration of the surface treated carbon cap with the silica base insulation, which otherwise would fail from mechanical, chemical or thermal factors. TUFROC is the first lightweight, low cost, flight proven, reusable TPS with sustained operational capabilities at temperatures above 3,000 degrees Fahrenheit (1648 °C).

Compared to the tiles used on the Space Shuttle, Elon Musk basically confirmed that Starship tiles are thinner, lighter, uniform and easier to inspect or replace. He added that there is no need for a sensor on each tile: “Tile itself is the sensor as it will partially ablate where too hot & have to be replaced.”

SpaceX is testing its version of the tiles on Starship prototypes. According to Elon Musk, the tiles are mechanically attached to steel studs and are not ablative. The aim of these early experiments is probably to verify how the attachment of the tiles handles the vibration from the engines as well as the temperature changes from multiple refuelings of cryogenic propellants. On the Starship SN4 prototype, SpaceX seemed to be testing two different types of attachment methods.

Detail of two different ways of attaching heat shield tiles on the Starship SN4 prototype (Credit: Nomadd / NASA Spaceflight)

Raptor Engine

Super Heavy Starship will be powered by full flow staged combustion Raptor engines that burn methane and oxygen. Methane has several advantages – it burns cleaner than kerosene used in Falcon rockets, so there is less coking on the engines (this helps with easy reusability), is cheap, and can be made on Mars (from hydrogen extracted from ice and from CO2 extracted from Mars atmosphere). The oxygen and methane mixture ratio would be at 3.6 to 1.

The Raptor will be the most powerful SpaceX engine with 2 MN of thrust, or roughly 2.5 times that of the Merlin 1D the Falcon rockets use. At the same time, it could be the highest thrust-to-weight ratio (TWR) engine in the world, outperforming Merlin 1D, the current record holder. However, Musk said that Raptor may not achieve thrust/weight & thrust/cost ratios higher than Merlin.

According to Musk, Raptor is designed for 1,000 flights with almost no maintenance, which is helped, among other things, by the use of hydrostatic bearings.

Regarding thrust throtlling, the 2016 Raptor was supposed to be able to throttle thrust down to 20%, but it proved to be a very difficult target. Elon Musk’s statement from March 2019 suggests that the first version of Raptor will only be able to throttle down to about 50%.

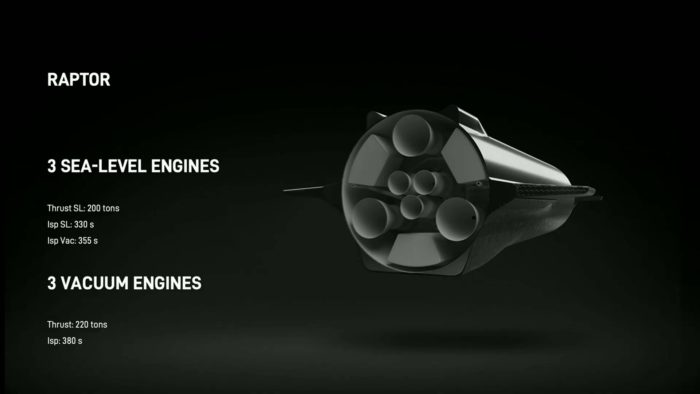

The original ITS concept from 2016 used more powerful Raptors with 3 MN of thrust, 42 engines on the first stage and 9 engines on the spaceship. The latest version of the rocket from 2018 is smaller and will use 31 Raptors on the first stage (the infamous Soviet N1 Moon rocket had 30 engines), while the spaceship will use 6 Raptors. A subscale Raptor prototype with 1 MN of thrust was tested in a test facility in McGregor, Texas starting in September 2016. Since then, however, the engine has undergone radical changes and “hundreds of improvements in manufacturability primarily”. Because of these changes, the engine is lighter and has higher thrust and Isp.

The first flight-worthy Raptor was shipped from Hawthorne to McGregor at the end of January 2019 and fired for the first time in early February. During the first week of testing, about 6 firings took place, one of which was approximately 11 seconds long and combustion chamber pressure of 268.9 bar was achieved. However, the engine was damaged during one of the tests.

Second manufactured Raptor was shipped to Boca Chica Village, Texas, where it was integrated into the Starship test vehicle dubbed Starhopper. The engine was then briefly ignited twice in April 2019. Third Raptor was spotted in McGregor in early April and was tested there (a 40-second firing was conducted at one point). The fourth Raptor was being tested in McGregor in May 2019. The fifth Raptor was supposed to be used for Starhopper’s initial hops but the engine was damaged during testing when it “liberated its oxygen turbine stator”. So Starhopper would instead use Raptor SN6, which was successfully tested in McGregor in July 2019 and then mounted on Starhopper.

In September 2019, Elon Musk stated that SpaceX was making Raptor SN12 (Serial Number 12), by December 2019 SpaceX has made 17 Raptors and in January 2020 the number increased to 20. In early March 2020, Musk said: “We’re on Raptor engine 23 or something, maybe 24. It’s lighter, cheaper, better in almost every way than Raptor version one, which sucked and blew up, basically. One of about six or seven Raptors that blew up, I’ve lost count.”

Elon Musk said that the company’s focus now was to ramp up build rate of Raptors and that SpaceX wanted to achieve production rate of one Raptor every 3 days in summer 2019. However, this wasn’t accomplished (possibly because Raptor’s design keeps being tweaked) and in November 2019, Elon Musk stated that the production would reach a rate of one engine per day at some point in 2020. By April, SpaceX completed 26 Raptors and in June 2020 the total reached 30 Raptors.

Merlin uses a pintle injector but Raptor uses a large number of coaxial swirl injectors, which SpaceX believes achieves highest theoretical mixing/combustion efficiency.

Raptor uses “milled copper channels with an inconel jacket all the way down” (made by “explosive hydro forming“) for regenerative cooling of the nozzle. Cold methane flows through these channels before it’s burned in the main chamber. Falcon’s Merlin engines are cooled in a similar way.

Unlike Merlin, Raptor does not use pyrophoric TEA-TEB (triethylaluminium triethylborane) for the initial startup. Musk revealed that methane gas and oxygen are ignited by heavy-duty spark plugs that “ignite dual blow torches that ignite preburners & main chamber.” Oxygen and fuel turbines need to “spool up super fast in unison” and therefore Raptor utilizes COPVs (composite overwrapped pressure vessels). According to Paul Wooster of SpaceX, these COPVs would not contain helium and would be refilled in-flight to allow the Raptors to reignite as needed.

Regarding production, Musk said: “Some parts of Raptor will be 3D printed, but most of it will be machined forgings. We developed a new metal alloy for the oxygen pump that has both high strength at temperature and won’t burn. Pretty much anything will burn in high pressure, hot, almost pure oxygen.” For this purpose, “SpaceX metallurgy team developed SX500 superalloy for 12000 psi, hot oxygen-rich gas. It was hard. Almost any metal turns into a flare in those conditions.” SX500 should be a monocrystalline modern version of Inconel superalloy (nickel + chromium). Parts of the Raptor are also cast from Inconel in the SpaceX foundry.

The long-term goal of SpaceX is to achieve 300 bar of pressure in Raptor’s combustion chamber, which was achieved in June 2020. However, Musk said in the past that 250 bar is sufficient for nominal operations. At a pressure in the main combustion chamber of more than 300 bar, the pressure in the oxygen preburner becomes a problem because it can reach over 800 bar which is “pushing the limit of known physics,” according to Musk.

The various BFR versions over the years always had an upper stage equipped with two types of Raptors, one type was optimized for operation in a vacuum while the other was optimized for atmospheric flight. However, in 2018, Elon Musk said that, in order to simplify development and production, SpaceX would initially develop only one version of Raptor for Starship, which would be used on both rocket stages. These plans changed again and Elon Musk explained in May 2019 that Starship would actually use 6 Raptors (instead of 7), with 3 of them being optimized for vacuum and 3 optimized for atmospheric flight.

The type optimized for operation in a vacuum will have 2.2 MN of thrust with a specific impulse (Isp) between 365 and 370 seconds (future iteration might reach 380 seconds). For comparison, Merlin 1D-Vac has Isp of 348 s and the RL-10 engine powering the Atlas V rocket has Isp if 451 s. The vacuum version of Raptor will be fixed to the airframe and will not have an extending nozzle like the RL-10 used on the Delta IV rocket, the diameter of the nozzle will be 2.8 meters. The goal is to gradually improve its thrust-to-weight ratio by 50%.

The second variant of Raptor optimized for atmospheric flight will have a specific impulse of around 356 seconds in vacuum and 2 MN of thrust. These engines will be mounted in the middle of the engine section and will be able to gimbal around 15 degrees which is necessary for precision landing.

SpaceX is also working on a third version of the Raptor, it would be optimized for atmospheric flight but wouldn’t be able to throttle or vector thrust. Because of this, it would be much simpler and therefore easier to manufacture. Also, it would allow higher maximum thrust over 260 tons (2.6 MN), eventually increasing to 300 tons. This engine would have a mass of 1,500 kg and thrust-to-weight ratio of 170 or more. For comparison, the current record holder Merlin 1D has a TWR of well over 150. The simplified Raptor would be used on the Super Heavy booster that can have up to 31 engines. However, only the 7 engines in the middle need to be able to throttle thrust and gimbal in order to land the rocet. Therefore, the remaining engines could be of the simplified variant. According to Elon Musk, this engine would be produced in the highest numbers.

Elon Musk also commented on Raptor’s cost. Everyday Astronaut estimated the engine cost to be around $2 million, but Musk said in June 2019 that while the cost was currently higher than that, it would drop to less than 10% when mass produced. Production costs keep dropping and should be reduced to below $1 million per each “Raptor V1”. The goal is to keep improving the engine and reach unit cost of $250,000 for V2, which would have 250 tons of thrust, meaning the cost per ton of thrust would be below $1,000.

Super Heavy (First Stage)

The first stage of the rocket is called Super Heavy, it will measure about 68 meters with a diameter of 9 meters and will be powered by 31 Raptor engines. Only the 7 center engines would gimbal (up to 15 degrees), while the outer engines wouldn’t gimbal and would be “mechanically joined at the nozzle“. It might look something like this:

Tight fit, but it works. 31 Raptors under Superheavy, with wiggle room for the center cluster pic.twitter.com/TU5zjYuJHa

— Rafael Adamy (@fael097) May 13, 2020

The production of the first full-sized Super Heavy was supposed to begin in late August 2019 but was delayed to late 2020. The initial launches will only use around 20 Raptors (instead of the full 31 engines), so as to risk less loss of hardware. SpaceX is in no rush to start manufacturing Super Heavy before the more complicated design of Starship is solved. Elon Musk said that Super Heavy development si simpler because it’s basically just a longer Starship tank without flaps or heat shielding. „The only thing that really changes is the aft dome where you’re transferring thrust load into the booster. You’ve got like 31 engines, that thrust dome obviously has to be unique, relative to the rest of the vehicle.“

Super Heavy will be made of stainless steel and structural strength will be achieved by having the tanks contain “welded, internal, longitudinal hat stringers” as well as slosh baffles to provide hoop stifness, if needed.

Super Heavy was originally supposed to have aerodynamic surfaces that would also serve as landing legs, but that plan was later changed and the booster will have legs similar to those on Starship (see the next section for more details). The booster will feature steel grid fins for control.

Starship (Second Stage)

Starship will measure 50 meters with a diameter of 9 meters, will be powered by 6 Raptors and will be have an integrated payload section able to carry over 1000 cubic meters of cargo, propellant or up to 100 people. The cargo bay will feature a large door to provide an opening 8 meters wide and 22 meters tall.

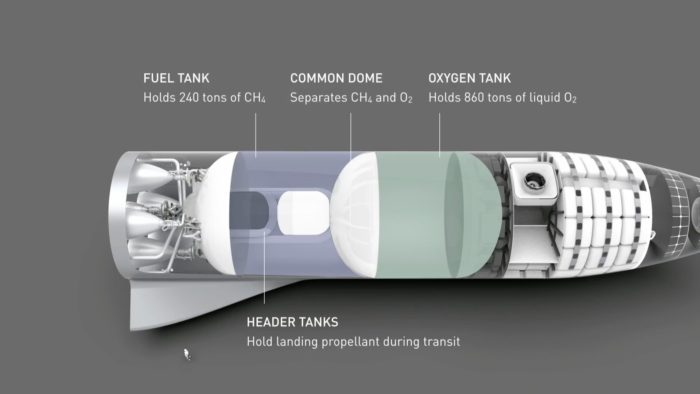

When Starship is upright, the top part is used for cargo or passangers. For crewed flights, the ship will have 40 cabins, each for 2 or 3 people, as well as common areas, canteens, shops and also a shelter where the crew can hide during a solar storm. The main methane tank is in the middle of the ship, with the main oxygen tank below it, and the engine section is at the very bottom. According to Elon Musk, the space around the engines will be used for cargo storage. It also helps manage center of mass for heavy payloads when forward cargo is full.

The empty space in the engine section can be used to store additional cargo, which “also helps manage center of mass for heavy payloads when forward cargo is full.”

The ship has radially-steerable forward canards and aft fins used for pitch control in a new reentry profile resembling a descending skydiver. According to Musk, these aerodynamic surfaces are needed for maneuverability in all axes at supersonic speeds and different angles of attack. Tesla batteries and electric motors in redundant configuration are used to move the massive control surfaces. Each rear flap needs ~1.5 megawatts of power.

Starship has six landing legs which are now separate from the flaps. They are folded inside the engine section and fold out right before landing. Elon Musk explained that the legs were telescopic and future versions would be longer, wider and auto-leveling to compensate for uneven landing surfaces. This will be especially useful for initial landings on the Moon or Mars, before flat landing pads are built there.

So Elon recently posted a bunch of closeups of the SN3 #Starships's underbelly.

In the photos you can see parts of the landing leg assembly, so I spent couple of hours trying to visualize how they might work.@elonmusk is this even remotely close? pic.twitter.com/Oq8YWaMuil— Kimi Talvitie (@kimitalvitie) April 1, 2020

The starship should contain up to 1,200 tons of fuel, of which about three-quarters would be oxygen. In regards to keeping the propellants at the right temperatures during long flights to Mars, Musk said in 2017:

The main tanks will be vented to vacuum, the outside of the ship is well insulated (primarily for reentry heating) and the nose of the ship will be pointed mostly towards the sun, so very little heat is expected to reach the header tanks. That said, the propellant can be cooled with a small amount of evaporation. Down the road, we might add a cryocooler.

Elon Musk also explained how Starship will be controlled on its way to the Moon or Mars. Vacuum Raptors will be able to throttle their thrust, but their position will be fixed. Therefore, the ship’s attitude will be controlled by gimballing the atmospheric engines running at minimal thrust. This way, most of the impulse would still go through the more efficient vacuum engines.

Starship renders also show fan-shaped solar panels to provide electrical power. However, the initial Starship prototypes were only equipped with Tesla battery packs. Renders also usually show several rows of small windows and one large window near the nose, but those would only be used on the crewed version of Starship.

For thermal protection, the steel surface will have stainless mirror finish for maximum reflectivity. The surface will not be painted because “it will get too hot”. Musk also said that the windows might have a gold tint. As for thermal protection of Raptor engines, Musk said: “Raptors must be shielded during atmospheric entry”. Therefore, the engines are actually hidden inside the ship’s body.

As for the ship’s interior, Elon Musk stated in September 2018 that various concepts had been developed. He pointed out that the interior would vary depending on type of mission. The interior of a ship going to Mars would be very different from the interior of a ship flying to the Moon, given the vastly different duration and the number of passengers. However, according to Musk, the interior design is important and the ship will have space for most fun activities that can be done in weightlessness.

Spaceship will not be equipped with a launch escape system. Musk said that because the rocket is reusable and will fly so often, its safety over time would be comparable to airplanes, so a typical crew escape system would not be needed. Modern airplanes also don’t have parachutes for passengers and one simply has to accept that there is a small chance of a tragic accident happening. However, it remains to be seen that SHS can really achieve this level of safety.

In addition to the main propellant tanks, Starship also has smaller header tanks that will remain full until the landing burn. According to Musk, this is important because otherwise there would be a risk that the engines will suck in an air bubble caused by the propellant floating around the tank in weightlessness after launch. Such a bubble could damage the engines. Therefore, Starship has smaller header tanks with propellant for landing. In the previous versions of the rocket, these tanks could be found inside the main tanks. But Musk later said that the design was simplified.

In the case of Starship Mk1, the header tanks were placed in the ship’s nose along with batteries and other hardware. The reason for this was to “balance high mass of Raptors & rear fins at the bottom“. However, starting with the SN4 prototype, the spherical methane header tank was moved from the nose to the bottom of the main fuel tank. The oxygen header tank is also spherical, weighs 30 tons and the plan still is to keep it in the tip of the nose cone.

Starship will have several different variants. There will be at least one crew version, a cargo version, a propellant storage version and also a tanker version which would be used to refuel other Starships in orbit. Musk said: “At first, the tanker will just be a ship with no payload. Down the road, we will build a dedicated tanker that will have an extremely high full to empty mass ratio (warning: it will look kinda weird).”

- Unofficial render of Starship’s cargo version (Credit: Kimi Talvitie)

- Unofficial render of Starship’s crewed version (Credit: Kimi Talvitie)

- Unofficial render of Starship’s tanker version (Credit: Kimi Talvitie)

Starship is made of “barrels”, 2-meter-tall rings with a diameter of 9 meters. They are manufactured by unrolling a sheet of stainless steel, cutting it and welding it. The resulting barrel weighs 1,600 kg and the tank section of each Starship consists of 17 barrels. Then the fairing needs to be added on top of that. SpaceX was producing two barrels a day in March 2020 and aims to eventually produce four a day.

Launch and Landing

SpaceX’s Environmental Assessment for the Starship and Super Heavy being used at the Kennedy Space Center in Florida, published in August 2019 (PDF), offered a lot of insight into how SpaceX plans to intitially conduct launches and landings.

A static fire test would be conducted on each stage prior to each launch. Super Heavy booster static fire tests would involve firing all Raptor engines for 15 seconds.

SHS maximum lift-off mass is approximately 5,000 metric tons. The booster would hold up to 3,600 tons of propellant and Starship would hold about 1,200 tons of propellant. During launch, the resulting plume is expected to reach ambient temperature at the point that it has traveled approximately 440 m. Noise levels are expected to be significantly higher compared to a Falcon 9 launch.

Less than 3 minutes after launch, the Super Heavy booster engines would cut off at an altitude of approximately 70 km and Starship would separate. Shortly thereafter, at an altitude of approximately 80 km, the Starship engines would start up and burn to the desired orbit location. After separation, Super Heavy would reach an altitude of about 130 km and then on descent reach hypersonic speeds above Mach 6

before slowing to subsonic speeds, below 8 km in altitude, prior to landing.

Originally, Super Heavy was supposed to land directly on the launch mount to enable quick reuse. However, since the plan to use strong methane control thrusters has been abandoned for now (see section “Super Heavy Starship System” above) and the rocket will therefore be equipped only with regular cold gas thrusters, landing directly on the launch pad will not be possible, at least initially.

One of the advantages of this type of landing was Super Heavy would not need to have landing legs. Now, the Super Heavy design had to be modified and as explained above in the Super Heavy section, the new engine layout indicates that lading legs would be foldable, similar to the Falcon 9 legs. Musk also explained that unlike Starship, the Super Heavy booster would not reenter belly first, as Super Heavy’s center of mass would be much lower than Starship’s and would be more consistent (no variable payload mass to consider), so it would tend to fly engines first just like the Falcon boosters.

According to Elon Musk, all seven of the Super Heavy’s center engines, which are able to gimbal by 15 degrees and thus control the rocket, would be used for the boostback burn. Musk hopes that the boostback would be strong enough to survive reentry without the need for an entry burn used by Falcon rockets to slow down. In that case, the Super Heavy would save propelland by only doing a landing burn. Super Heavy would be steered using grid fins, just like the Falcon boosters. However, the ones on Super Heavy would have a different shape and would be made of welded steel instead of titanium.

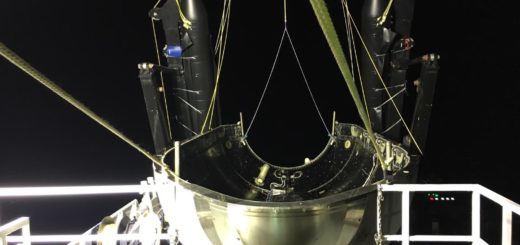

So how will the landing actually work? At least initially, Super Heavy would always land on a droneship, just like the Falcon 9 boosters do now. The droneship would be positioned at least 37 km offshore.

The Starship spacecraft would initially use the existing LZ-1 landing pad on Cape Canaveral where Falcon booster regularly land. However, SpaceX also wants to eventually build a new 85-meter-diameter landing pad inside the 39A launch complex. As a contingency, Starship would also be able to land on a droneship like the Super Heavy. Starship landing on LZ-1 would cause sonic booms that could be heard in a much larger area compared to Falcon 9 boosters landing.

When returning from orbit, Starship will reenter at 60-degree angle and will be steered using four separately-controlled flaps. Two of them are on the nose and two in the aft section. According to Elon Musk, they “generate lift in the hypersonic regime, which is important to limit peak heating”. In other words, Starship will want to maximize time spent aerobraking. For interplanetary missions, multiple aerobrake passes will be needed.

Before landing, Starship will use its cold-gas thrusters and Raptor engines to shift to a vertical orientation:

After landing vertically on LZ-1, Starship would go into an automatic safing sequence that would vent any remaining liquid oxygen or methane. After the vehicle is in a safe state, a mobile hydraulic lift would raise Starship onto a transporter, similar to the current transporter used for Falcon. The Starship would be transported from the landing pad back to LC-39A or to another location for refurbishment.

Musk also suggested an alternative way of transporting Starship after it lands. SpaceX could “attach wheels to the landing legs & tow Starship to the launch pad”, possibly by a Tesla Cybertruck.

SHS Production

According to Gwynne Shotwell, SHS cannot be manufactured at SpaceX’s factory in Hawthorne due to its dimensions, as it would be very expensive to transport such large parts by road:

We thought we’d build [the BFR] in our factory in Hawthorne, but we priced transport to the harbor, and it came out to $2.5M per trip. It would require taking down stoplights, and just wouldn’t be worth it. So we will build a new facility by the water. We will eventually also have a number of production sites by our launch sites.

In April 2018, SpaceX leased property in Port of Los Angeles to build a rocket factory for $1.38 million a year. However, SpaceX abandoned these plans in January 2019 and in March 2019, Elon Musk announced that Starship & Super Heavy would be built near launch pads in both Boca Chica and Cape Kennedy simultaneously. However, in January 2020, SpaceX resumed talks with city officials to build a Starship factory in Port of Los Angeles after all. But these plans were also canceled shortly afterwards.

SpaceX’s Environmental Assessment for the Starship and Super Heavy being used at the Kennedy Space Center in Florida, published in August 2019 (PDF), mentioned that fabrication and assembly of launch vehicle components would occur at existing SpaceX facilities located on KSC and CCAFS. These facilities could include Area 59 and the Payload Processing Facility (PPF) on CCAFS, the Falcon Hangar at LC-39A, and the soon to be constructed KSC SpaceX Operations Area on Roberts Road. SpaceX would also perform fabrication, assembly, and integration operations at the Mobile Service Station (MSS) Park Site Property and on the Crawlerway area. Staging and temporary fabrication tents could be used on the Crawlerway to support operations.

In another part of the assessment, SpaceX said that most manufacturing of vehicle components would occur at the SpaceX facility in Hawthorne, CA. Additional facilities being considered for manufacturing and assembly include Boca Chica, TX, and a facility in the Cidco Industrial Park, Cocoa, FL. However, this information is likely outdated because SpaceX later decided to focus all Starship activities to their Boca Chica facility.

Starhopper Test Vehicle

In South Texas, a short distance from the SpaceX launch pad near Boca Chica Village, the first Starship development vehicle started being built in December 2018. This experimental rocket, dubbed Starhopper, was built to conduct low-altitude test flights and will be equipped with up to three Raptor engines. But it’s probably going to be quite different from the final design of the ship, similarly to how Falcon 9 didn’t have that much in common with Grasshopper, which SpaceX used in 2012 and 2013 to test booster landings.

Completely assembled, non-functional Starhopper without engines or plumbing in January 2019 (Credit: Elon Musk)

Brief history of Starhopper:

- On January 11, 2019, Starhopper was assembled for a photo session, but it was only an empty shell without functional engines, tanks, etc.

- Starhopper was then disassembled into two halves and work started on the lower half’s internals

- At the end of January, strong wind gusts tipped over and destroyed the hollow upper half of Starhopper

- In the following weeks, work on the lower half continued – tanks, cabling, piping, foot reinforcements, etc.

- On March 8, the completed lower half was transported to the nearby SpaceX launch pad

- On March 11, a new Raptor engine was shipped to the pad and few days later was installed on Starhopper

- On April 4, Starhopper was static fired for the first time (duration around 3 seconds). Two days later, another short firing occured. Afterwards, the Raptor engine was removed from Starhopper for unknown reason and then shipped to Hawthorne.

- In early June, a new Raptor was installed on the Starhopper but was soon removed again.

- While waiting for another Raptor, a new landing pad was built.

- On July 11, Raptor SN06 was mounted on Starhopper in preparation for its first untethered flight.

- The first short flight took place on July 26 when the vehicle successfully hopped to an altitude of 20 meters.

- In August 27, Starhopper flew to an altitude of 150 meters. It was its last flight.

- The plan is to use Starhopper as a vertical test stand for Raptor engines.

According to Musk, the prototype has the same 9-meter diameter as the Starship design but is shorter. The total height of Starhopper is estimated at 40 meters, while the final orbital rocket should be about 50 metres tall. However, Starhopper is actually only about 20 meters tall because it’s missing the large nose cone that was destroyed in January 2019. SpaceX chose not to replace it because the nose cone was not needed for the planned test flights.

- Starhopper during transportation to the launch pad (Credit: bocachicagal / NASA Spaceflight forum)

- Starhopper during tank tests(Credit: bocachicagal / NASA Spaceflight forum)

- Starhopper with installed Raptor engine (Credit: bocachicagal / NASA Spaceflight forum)

- Starhopper during its first static fire in April 2019 (Credit: bocachicagal / NASA Spaceflight forum)

Starship Prototypes

Starhopper is only designed for relatively simple and short flights to low altitudes, but SpaceX plans more advanced tests. In February 2018, Elon Musk described the test flight plan as follows:

We’ll do flights of increasing complexity. We really want to test the heat shield material. So we’ll like fly out, turn around, accelerate back real hard, and come in hot, to test the heat shield. Because we want to have a highly reusable heat shield that’s capable of absorbing the heat from interplanetary entry velocities.

The first Starship prototype was called Mk1 (Mark 1) and was built in South Texas during 2019, in the same place where the Starhopper was assembled previously. This test article was much closer to Starship’s final design and was fully assembled in September 2019 for Musk’s presentation about Starship.

- Starship prototype being built in Florida in June 2019 (Credit: Bill Carton)

- Comparison of Florida and Texas prototypes in June 2019 (Credit: Tom Cross / Teslarati)

- Starship Mk1 being built (Credit: SpacePadreIsle / Twitter)

- Fully assembled Starship Mk1 (Credit: Elon Musk)

In May 2019, it was revealed that SpaceX was actually making two orbital prototypes simultaneously. In addition to Texas, another prototype (called Mk2) was being produced in Cocoa, Florida, about 45 km away from LC-39A. Elon Musk explained that SpaceX had two teams that simultaneously worked on Starship prototypes in both Texas and Florida and competed with each other to see who will be faster. He said that both locations will make lots of Starships and the goal of this friendly competition is to find out which location is the most effective. The teams share their knowledge but each can choose their own approach and do not need to follow the advice of the other team.

However, in late 2019, it started looking like Mk2 would never fly and SpaceX was moving most of their Starship efforts to Texas where Mk1 was built. That said, SpaceX is also building another facility in Kennedy Space Center (Roberts Road) where Starship might be built in the future. Compared to the Cocoa facility, transportation of the finished spacecraft from Roberts Road is easy due to its proximity to LC-39A.

In November 2019, SpaceX started testing the Mk1 prototype in Texas. The plan was to do a few wet dress rehearsals, a static fire and eventually conduct a test flight to an altitude of 20 km. However, during one of the initial tanking tests, Mk1 exploded while being filled with cryogenic nitrogen, and was destroyed. After the accident, Elon Musk stated on Twitter that SpaceX would scrap Mk1 and would instead focus on building the next prototype Mk3 with an improved design.

Starship Mk1 had dry mass of 200 tons but future versions are supposed to be lighter (about 120 tons or less). This will be possible thanks to “exponential improvements” in design and manufacturing. For example, prototypes Mk1 and Mk2 were welded from many smaller pieces of stainless steel, but the newers ones are built from barrel sections made from just one piece of steel and requiring only one weld. The barrel sections are taller and thinner which makes the entire Starship lighter.

The Mk3 prototype was eventually renamed SN1 and is supposed be the first example of “Starship V1.0” designed for orbital launches. SN1 was built in Boca Chica, which became the main facility dedicated to Starship. Teams in Florida would instead focus on Falcons and Dragons. Starship SN1 failed during cryogenic pressure test in late February 2020.

SpaceX then made and tested many more Starship prototypes and test tanks. SN4 was the first one to pass cryogenic testing and conducted several static fires. It was supposed to do a short hop but a few days prior to the flight, the prototype exploded after a static fire. SN5 or SN6 are now expected to be the first Starship prototypes to fly (first to an altitude of 150 meters and later to 20 km). This will allow SpaceX to test out flaps, engine restarts and landing maneuvers. The following unofficial animation shows what a longer test flight could look like.

Eventually, SpaceX will start doing orbital launches. Elon Musk hopes the first one could happen by the end of 2020. Orbital launches will require the Super Heavy booster, with the first one to be manufactured in late 2020. According to Elon Musk, the payload for the first orbital Starship launch couId be Starlink satellites and some fun things.

You can learn more about the various Starship prototypes in this maintained list (auto-translated).

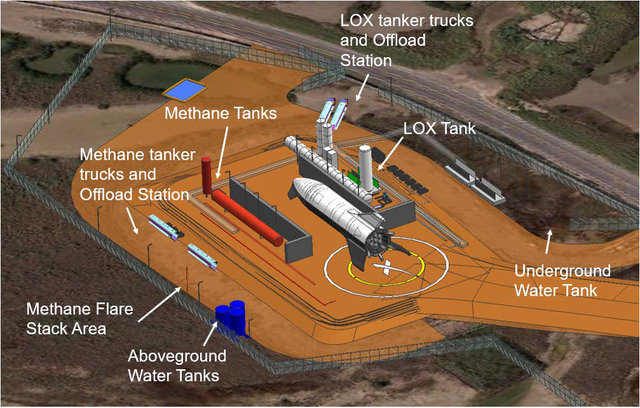

Launch Pads

There is a new launch pad being built in South Texas . Originally, Falcon 9 and Falcon Heavy was supposed to launch from this pad, but few years later it was decided that the pad would be used primarily for Super Heavy Starship. SpaceX already has three pads for Falcon rockets, so there isn’t a great need for more, especially since SHS is supposed to eventually replace both Falcon 9 and Falcon Heavy anyway.

The pad is located in southern Texas near Boca Chica Village and Brownsville. SpaceX bought the land in 2012 but significant construction work didn’t start until 2018 for various reasons. In 2019, SpaceX conducted test flights of Starhopper here. Further testing of various Starship prototypes is also planned.

Boca Chica launch pad (Credit: FAA)

Elon Musk stated that Starships would also launch from the existing pad 39A at the Kennedy Space Center. Currently, Falcon 9 and Falcon Heavy rockets launch from this pad and Musk said that that wouldn’t change and “Starship launch structure will be attached to the other side from tower.” Construction work started in late 2019.

Photos of the #spacex #starship flame diverter at 39A from today. Doesn't look like much has changed since my last visit. pic.twitter.com/TbtHMfvBfP

— Jared Frankle (@JFranklephoto) December 30, 2019

According to the official environmental study, SpaceX plans to build a secondary launch mount for Starship at LC-39A approximately 100–200 meters southeast of the existing Falcon mount. The Starship launch mount would be placed at a height of 30 meters to reduce excess recirculation and erosion from rocket exhaust. A flame diverter would be constructed instead of a flame trench as is currently used at the Falcon launch mount. The flame diverter would be composed of metal piping similar in construction to the SLC-40 water-cooled diverter. It would measure approximately 20 m wide by 20 m tall and be positioned directly under the rocket. A new road connecting the Starship launch mount and the existing Horizontal Integration Facility would be built.

New equipment would also be added to LC-39A to support Starship launches. There would be new water towers for the deluge system. And because Starship uses different fuel than Falcons, there would be a new methane farm built. It would accommodate a total capacity of approximately 2 million kg of methane. Approximately 1.5 million kg of liquid nitrogen, used to cool the methane, would also be stored in the methane farm. The existing flare system used during the Shuttle program would be refurbished and used as a methane flare. If this is not feasible, a new flare stack would be installed near the methane farm.

The rocket would be integrated vertically on the pad at LC-39A using a mobile crane. This would involve the booster being mated to the launch mount followed by Starship being mated to the booster. Initial

flights would use a temporary or mobile crane, with a permanent crane tower constructed later. The height of the permanent crane tower would be approximately 120 to 180 m.

NASA Spaceflight reported that test flights of the Starship prototype being built in Florida might eventually launch to orbit even without the Super Heavy booster. That would make Starship the first ever SSTO (Single Stage to Orbit). However, Elon Musk responded by saying that while Starship technically could SSTO, it wouldn’t have enough mass margin for a heat shield, landing propellant or legs, so would not be reusable. That makes SSTO launches unlikely.

The work on the Starship launch pad at LC-39A stopped a few months after it had started, when SpaceX decided to focus all their Starship efforts to Boca Chica.

SHS Applications

SpaceX intends to offer SHS for virtually any conceivable purpose. Musk mentioned the possibility of launching many smaller satellites at the same time, or creating new types of satellites that would benefit large payload section of Starship. No other company currently offers such a service so the size of satellites is often limited by the dimensions of fairly small payload fairings on regular rockets. Musk gave an example of a space telescope that, if launched on SHS, could have a mirror 10 times larger than the Hubble Telescope without any complicated folding. Coincidentally, NASA did a study to determine if SHS could be used to launch a gigantic space telescope LUVOIR with a mirror diameter somewhere between 8 and 18 meters. Additionally, SHS could collect old satellites or space debris if there is interest in the industry, Musk suggested. The rocket is also capable of supplying the International Space Station.

For most of these purposes, the Falcon family of rockets can be used, but not only is SHS supposed to be cheaper to operate thanks to full reusability, it can also deliver cargo efficiently to more distant destinations like the Moon or Mars. However, multiple launches are required because Starship needs to be refueled on orbit before embarking on these longer journeys.

SpaceX would like to have SHS operational as soon as possible. The company needs to launch nearly 12,000 satellites (not a typo) by 2027 for Starlink, its satellite constellation that would provide fast and cheap internet connection worldwide, and using Falcon 9 to launch all these satellites would be uneconomical or maybe even impossible. Elon Musk said at the end of 2018 that Starlink V1 would launch on Falcon, V2+ on Starship.

SHS is also capable of providing extremely fast intercontinental transportation for up to 1000 passengers. In this scenario, SHS would launch from one of many floating launch platforms that would be close to big cities. Starship would then separate from the booster that would then land somewhere while the spaceship with passengers would continue on its way. Then, Starship would land near the destination city on a floating platform similar to the one it launched from. Most of these long-distance trips would take about 30 minutes. You could reach even the farthest place on Earth within an hour. According to Musk, the price for this mode of transport would be comparable to regular airline tickets and, according to SpaceX President Gwynne Shotwell, the service will be operational by 2028.

In May 2019 Elon Musk said that his team realized that adding 2 to 4 more Raptors to Starship enables much easier point-to-point travel. This configuration „dramatically improves cost, complexity & ease of operations“ because you don’t need the Super Heavy booster. Musk added: „Distances of ~10,000 km with decent payload seem achievable at roughly Mach 20.“

Financing the Development of SHS

During the dearMoon event in September 2018, Elon Musk said that less than 5% of SpaceX resources were used for the development of SHS and only when the company had a Falcon and Dragon operations going smoothly would employees gradually shift focus to the SHS project. Musk expects that by the end of 2019, most engineers will be working on SHS.

Musk estimates the total cost of developing SHS to be about $5 billion, but he said it’s very hard to estimate. He added that it would certainly be more than $2 billion but probably less than $10 billion. By comparison, the development of the Falcon 9 and Falcon Heavy rockets cost between 1 and 2 billion dollars total.

SpaceX intends to fund the development of SHS with profits from launching commercial satellites, crew and cargo to the ISS and also the Starlink service. Another source of revenue would be deposits from customers like Yusaka Maezawa (see Project dearMoon below). The company can also continue to generate profits from Falcon operations, especially since the rockets should soon be able to be reused quickly and easily thanks to the Block 5 upgrades. According to Musk, SpaceX can stockpile Falcon stages and gradually stop making them altogether. Thanks to their reusability, they would be able to keep using them long after their production ends.

Moreover, thanks to the reusable first stage and fairing that together account for 80% of the cost of the entire rocket, the company would significantly increase its net profit from each launch. There is currently no reason for them to transfer savings from reusability to the customers by lowering the launch price, as SpaceX launches are already much cheaper than the competition. After SHS starts launching, customers will have the choice of having their cargo launched on a proven, and presumably more expensive, Falcon, or a new and more risky SHS that would be cheaper.

The U.S. Air Force contributed funds to the development of the Raptor engine.

NASA announced in July 2019 that it will work together with SpaceX and other companies on developing various technologies that could be used for lunar missions:

- SpaceX will work with NASA’s Kennedy Space Center in Florida to advance their technology to vertically land large rockets on the Moon. This includes advancing models to assess engine plume interaction with lunar regolith.

- SpaceX will work with Glenn and Marshall NASA centers to advance technology needed to transfer propellant in orbit, an important step in the development of the company’s Starship space vehicle.

SpaceX is also one of several companies that will bid on NASA contracts to launch useful payloads to the lunar surface. In addition, SpaceX received $135 million from NASA as part of the first phase of a contract to develop a human landing systems for Artemis astronauts. If development goes well, much more funding could be secured in the later phases. More information can be found below in the Moon Missions section.

Project dearMoon

Japanese billionaire Yusaku Maezawa paid a large sum of money for a week-long trip in Super Heavy Starship around the Moon and back. When he announced these plans in September 2018 , he also confirmed that he was the mysterious customer who paid SpaceX in 2017 for a flight around the Moon in Crew Dragon. But because the mission required Falcon Heavy, a rocket that SpaceX does not plan to certify for crewed flights, the trip will be done using SHS instead.

Maezawa is an art lover so he wants to share this unique space experience with other artists from around the world (painter, photographer, filmmaker, etc.) who will fly with him around the Moon. He believes that the works of art that will be inspired by the artists’ experience will contribute to world peace and awaken the dreamers in all of us. Maezawa calls this art project dearMoon and the current plan is to fly around the Moon in 2023.

The exact moon flight profile is not yet finalized, but the trip should take about 6 days. SHS will launch from Earth with Maezawa and 6 to 8 other artists on board and Starship will reach parking orbit around Earth. Then, the engines will be fired to guide the ship to the Moon where it will arrive in 2 days. Passengers will thus become the first private persons to get beyond Earth’s orbit. The flight phase near the Moon will take about a day, and then the ship will begin to return back to Earth, landing 2 days later. Elon Musk hopes to plan the mission in a way so that the ship gets very close to the Moon’s surface.

During the project’s announcement, Elon Musk stressed several times that it was a risky mission: “It’s a dangerous mission. We will do everything we can to minimize risks, but something might go wrong. Yusaku is a brave man.” Since this mission will carry only a few people, far below the maximum capacity of SHS, Musk said it would allow them to bring a lot of spare oxygen and other supplies with them in case there’s a problem during the journey. Musk wasn’t sure if a test Moon flyby with an empty SHS would be done prior to the real launch, but then said it probably would. At the same time, he explained that since the flyby would take only a few days, unlike a journey to Mars which takes months, there would be no need for a complicated closed-loop life support system where all water and other substances would be fully recycled. Instead, lunar missions can use the life support systems that SpaceX developed for Crew Dragon missions to the International Space Station.

Musk said that the journey would be livestreamed in virtual reality so that everyone could see what it’s like to be on board. He added that the Starlink satellite constellation, which should be in operation by then, could be used to transfer the data.

Maezawa declined to say exactly how much he had paid for the trip but Musk said it was a large sum that will cover a significant portion of the costs to develop SHS. Maezawa confirmed that he had already paid SpaceX a considerable advance.

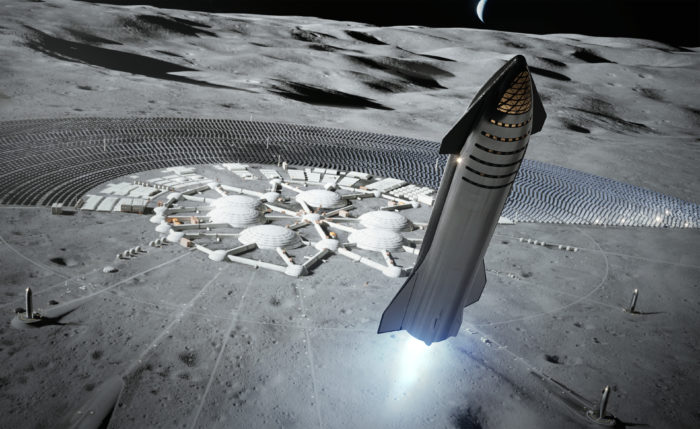

Moon Missions

Given that the current US government administration is very interested in going to the Moon, both Gwynne Shotwell and Elon Musk expect that SHS will first undertake missions to the Moon and only later to Mars. Gwynne Shotwell hopes it will be in building a permanent monthly base. Musk explained that going to the Moon first is better because “it’s only 3 days away and you don’t need interplanetary orbital synchronization” (which occurs only every 26 months in the case of Mars). According to Shotwell, Starship should land on the Moon by 2022. The plan is to leave useful cargo on the surface that could be used by NASA or other companies. Shotwell also said that a crewed Starship could land on the Moon in 2024.

NASA announced in April 2020 that it has selected designs from Dynetics, Blue Origin and SpaceX, which are developing lunar landing systems for NASA astronauts to land on the Moon in 2024 as part of the Artemis program. For these purposes, SpaceX has designed a simplified version of its Starship spacecraft. After refueling in Earth’s orbit, this lunar Starship could transport up to 100 tons of cargo to the Moon in addition to transporting astronauts from the Moon’s orbit to the surface and back.

The most significant changes compared to a regular Starship is the absence of aerodynamic control surfaces (flaps) and the heat shield. These features are only needed during the return to Earth, but in this case the lunar Starship would remain on the Moon. The official pictures of the lunar variant of Starship also show that solar panels would be placed on the tip of the ship and the astronauts would get from the ship to the Moon’s surface by some sort of an elevator.

The deceleration of the ship before landing on the Moon would be done by firing Raptor engines, but these would then be shut down and the final phase of the landing maneuver would use new methane thrusters at the upper part of the ship. The reason is that the Raptors are so strong that it would be impossible to land on the surface of the Moon without a landing pad. The Raptors would essentially blow out a crater in the regolith and the ship would tip over upon landing. In addition to that, the lunar dust would be accelerated so much that it could reach orbit and potentially cause further issues. For this reason, SpaceX has been studying the effects of engine plumes on the lunar regolite during Starship landing in cooperation with NASA. Smaller methane thrusters are a solution to this problems. The same thrusters would also be used to launch from the surface.

SpaceX also said that by the time Starship would need to transport astronauts to the Moon’s surface in 2024, the ship and booster should have completed many missions. These can serve as a demonstration of the technologies needed to safely conduct a lunar mission for NASA. Specifically, SpaceX expects that Starship will have achieved the following milestones by 2024:

- Launch of the Super Heavy booster

- Flight of a reused Starship

- Long duration Starship orbital flight

- Starship flight beyond low Earth orbit

- Starship orbital refueling demonstration

- Uncrewed Starship landing on the Moon in 2022

Mars Missions

Elon Musk somewhat optimistically hopes that two SHS rockets could go to Mars as early as 2022. These initial launches to Mars would be uncrewed and their main purpose would be to identify potential risks, confirm the presence of water in the target area, and to deliver essential equipment needed to provide energy and life support for future missions and set up a mining operation.

The optimal launch window for trips to Mars opens once every 26 months, so if the 2022 cargo missions to Mars succeed, Musk thinks, first people could go to Mars in 2024. This time, four Starships would launch within the launch window – two with crew and two with cargo. The main purpose of this mission would be to launch SpaceX’s fuel production plant and build a small base that could be expanded in the future. SpaceX’s Paul Wooster expects that many of the Starships would stay on Mars and serve as habitats for the first settlers.

Elon Musk estimates that it will take at least 10 launch windows for the base to become self-sufficient, so in 2050 at the earliest. In a 2017 presentation, Musk showed how the development of a Mars base could look like. The base centers around Starships and a solar-powered plant that makes methane and oxygen out of Mars ice and atmospheric carbon.

For regular people, the price for a ticket to Mars will be based primarily on the number of passengers, according to Musk. But he believes that the cost of moving to Mars (the return flight is free) will one day fall below $500,000 and maybe even below $100,000. That is a low enough for people in developed countries to sell their house and other earthly possessions and move to Mars if they wished.

That said, Musk pointed out in 2018 that all of these plans are very theoretical and that for the time being, it is not certain that SHS will ever even fly successfully. He acknowledged that the whole project could fail, but also pointed to the rapid advancements that SpaceX has made over the past 10 years. In 2008, the company celebrated its first ever successful launch with a small Falcon 1 rocket, and only 10 years later, Falcon Heavy launched for the first time, the most powerful rocket in the world today. Also, SpaceX dominates the commercial launch market and its Falcon rockets are mostly reusable. Musk thinks you might not have found a single person in 2008 who would say that SpaceX could accomplish something like that within 10 years. Even he himself did not believe at that time that such a thing could be achieved. In other words, SpaceX is much more experienced today and no one can even guess what the company will achieve in the next 10 years.

Elon Musk also keeps looking ahead. He stated in August 2019 that the next generation of Starship could have the diameter of 18 meters, or twice the size of the current design.

Relevant Links and Videos

- Official Starship website

- Official Starship User’s Guide

- Official dearMoon website

- ITS/BFR/SHS and other SpaceX wallpapers

- Elon Musk’s 2017 Reddit AMA about BFR, Raptor and Mars

- Interplanetary Transport System Animation

- Elon Musk’s 2016 ITS Presentation

- Elon Musk’s 2017 BFR Presentation

- Elon Musk’s 2018 BFR/dearMoon Presentation

- Evolution of the Big Falcon Rocket (NASASpaceflight.com)

Did you enjoy this article? Check out similarly detailed Compendiums about other SpaceX topics: Starlink, Falcon Heavy, OctaGrabber, Fairing recovery and more…

Changelog:

- Jul 1, 2020 – Huge update based on news from the last several months (mainly about Super Heavy, Starship prototypes and lunar Starship)

- Feb 7, 2020 – Finally got around to properly update the entire article based on Musk’s 2019 presentation and other news in the last weeks and months

- Aug 4, 2019 – Added a new section about launching and landing Starship and Super Heaby + added new information about SpaceX’s plans for launching Starship from LC-39A and other tidbits from the recently published Environmental Assessement

- Jul 28, 2019 – Added new information about Starship’s possible ceramic heat shield, updated Super Heavy engine layout and the first Starhopper flight

- Jul 13, 2019 – Added new information about Starship’s payload capabilites and new developments with Raptor, Starhopper and the orbital prototype in Texas

- Jun 27, 2019 – Added new information about Raptor and Starship based on Musk’s recent tweets + added some pictures of Starhopper and the two Starship prototypes being built

- Jun 3, 2019 – Added new information about Raptor’s vacuum variant and Starship’s wings redesign, updated Super Heavy timeline, current Starhopper progress and the possibility of point-to-point travel without Super Heavy (all based on Musk’s recent tweets)

- May 23, 2019 – Added information about Raptor and Starship’s changed engine configuration based on Musk’s recent tweets

- May 20, 2019 – Added information about the second orbital prototype being built in Florida + information about Raptor SN6 through SN10 + unconfirmed reports about Starship prototypes launching from LC-39A and the possibility of SSTO

- Apr 30, 2019 – Added information about 40-second Raptor test firing + added new official Starship renders

- Apr 16, 2019 – Added some information about Starhopper progress and more details about the orbital prototype that’s being built

- Apr 4, 2019 – Added information about Starhopper static fire and third Raptor being tested in McGregor

- Mar 25, 2019 – Article first published

First of all this a great website and keep up the good work.

Thanks, I’m glad you like it.

Great work!

Nice summary. The key to maintaining its usefulness, and thus its popularity/engagement, will be to keep it up to date. This is going to be hard, as the project is developing (and changing) rapidly.

Best wishes.

Ben

I’ve been maintaining the Czech version for a few months now so I know what it involves. 🙂

Fantastic resource and really well put together. A few minor suggestions:

In the sentence “In addition to the main propellant tanks, Starship will also have smaller header tanks that remain until the landing burn.”

You probably mean “…Starship will also have smaller header tanks that will remain full until the landing burn.” or something similar

The last quote from Elon in the Starship (Second Stage) section has an unnecessary open quote mark.

” “At first, the tanker will just be a ship with no payload.

“expensice” should be “expensive”

Thank you, it’s fixed now. 🙂

Great Work! Only one comment. Per Elon Musk’s comments, it seems that SHS won’t use nitrogen thrusters for maneuvering and they will use some type of methane thrusters. “The BFS will have methalox RCS thrusters for spaceship attitude control”:

Reddit AMA: https://www.reddit.com/r/space/comments/76e79c/i_am_elon_musk_ask_me_anything_about_bfr/

That was the original plan but, as explained in the article, Elon recently said that SHS will only have regular nitrogen thrusters (at least initially).

Did the height of SuperHeavy change or is that first fan rendering of SuperHeavy 7.5m too tall? (If there is an interstage in there, which doesn’t make sense in a fully reusable setup, that still doesn’t seem to account for the extra height)

In reference to the cross-section of 2017 Starship showing header tanks. I am just wondering that what insulation method is used on CH4 line that passes through the lox tank. Is SpaceX using vacuum jacketed pipe?

I don’t think there is any insulation. The methane and LOX should be at pretty similar temperatures. That’s why you can also have a common bulkhead that doesn’t need insulation.